Upgrade Your Heat Exchanger Without Full Replacement

Save time, money, and hassle — replace the tubes, not the entire unit.

At Teralba Industries, we’re committed to providing smarter, more cost-effective solutions that extend the life and performance of your process equipment. One of our most valuable and unique offerings is our Dimpled Tube Retrofit Service — a specialized maintenance solution that allows you to replace worn or aging heat exchanger tubes with advanced dimpled tubes, without the need to replace the entire unit.

⚠️ The Challenge

Why Full Replacement Isn’t Always Necessary

When the performance of a heat exchanger begins to decline—often due to tube corrosion, fouling, or reduced thermal efficiency—the default recommendation is usually full unit replacement. This “rip and replace” approach might solve the immediate issue, but it comes with serious costs and operational disruptions that are often avoidable.

High Capital Expenditure

Replacing an entire heat exchanger can involve tens—sometimes hundreds—of thousands of dollars in new equipment, installation, and engineering adjustments. This isn’t just a purchase; it’s a major capital project that impacts your budget and long-term planning.

Extended Downtime

Full unit replacement means taking your system offline, coordinating trades, and often waiting weeks for new parts to arrive and be installed. That lost production time can be just as costly as the equipment itself—especially in high-output environments.

Plant-Wide Disruption

Heat exchangers are typically integrated into broader processing systems. Removing and reinstalling a new unit can require reconfiguration of piping, supports, and controls. This creates a ripple effect across your plant’s workflow, increasing risk and complexity.

💡The Smarter Solution

The Dimpleflo™ Tube Replacement Solution

Upgrade Your Heat Exchanger with Proven, Patented Dimpleflo™ Technology

At Teralba Industries, we believe you shouldn’t have to replace an entire heat exchanger just because the internal tubes have aged or corroded. That’s why we offer the Dimpleflo™ Tube Replacement — a smarter, more efficient way to restore and enhance your system’s performance without the time, cost, or disruption of full-unit replacement.

Replace the Tubes, Not the Unit

Our retrofit service involves carefully removing the worn or inefficient internal tubes from your existing heat exchanger and replacing them with Dimpleflo™ dimpled tubes — precision-engineered to significantly boost heat transfer and efficiency.

Retain Your Existing Setup

There’s no need to alter your infrastructure. The Dimpleflo™ tubes are custom-manufactured to fit perfectly within your current heat exchanger shell, maintaining the original layout and flow paths while delivering a major performance upgrade.

Custom-Engineered for Seamless Integration

Each retrofit is tailored to your specific equipment. Whether you're running a compact CIP system or a large-scale processing plant, our engineering team ensures the retrofit matches your application exactly — down to the millimetre.

Trusted Across Critical Industries

- Food and Dairy Processing

- Beverage and Brewing

- Pharmaceutical Manufacturing

- Chemical and Industrial Processing

- Heavy Industries like Oil & Gas, Mining & more.

Replace the Tubes, Not the Unit

Our retrofit service involves carefully removing the worn or inefficient internal tubes from your existing heat exchanger and replacing them with Dimpleflo™ dimpled tubes — precision-engineered to significantly boost heat transfer and efficiency.

Retain Your Existing Setup

There’s no need to alter your infrastructure. The Dimpleflo™ tubes are custom-manufactured to fit perfectly within your current heat exchanger shell, maintaining the original layout and flow paths while delivering a major performance upgrade.

Custom-Engineered for Seamless Integration

Each retrofit is tailored to your specific equipment. Whether you're running a compact CIP system or a large-scale processing plant, our engineering team ensures the retrofit matches your application exactly — down to the millimetre.

Trusted Across Critical Industries

- Food and Dairy Processing

- Beverage and Brewing

- Pharmaceutical Manufacturing

- Chemical and Industrial Processing

- Heavy Industries like Oil & Gas, Mining & more.

Why Choose The Dimpleflo™ Tube Replacement?

When heat exchanger tubes begin to deteriorate, the traditional solution has been costly full-unit replacement. Teralba offers a better path forward. By retrofitting your existing heat exchanger with dimpled tubes, you gain access to cutting-edge performance advantages while avoiding the capital expense of new equipment.

Key Benefits of Upgrading to Dimpled Tubes

Boost Heat Transfer Efficiency

The Dimpleflo™ tubes disrupt the flow of fluid inside the tube, promoting turbulence that significantly improves heat transfer. This leads to faster thermal response and better control over your processes.

Increase Process Throughput

With improved heat exchange, your systems can handle higher product volumes in shorter cycles, enhancing overall productivity and allowing you to scale operations without expanding your plant footprint.

Reduce Energy and Operating Costs

Improved thermal efficiency means you use less energy to achieve the same or better outcomes. This leads to lower utility costs and a reduced environmental footprint.

Extend Equipment Life

By replacing only the internal tubes, you maintain the structural integrity of your current heat exchanger while eliminating worn-out components — extending the life of your asset and avoiding downtime associated with complete replacements.

Minimise Capital Expenditure

Avoid the significant costs of purchasing and installing new heat exchangers. Our retrofit solution is a smart, economical alternative that delivers long-term value.

Tailored to Your Existing Equipment

Our experienced technicians custom-fit the new dimpled tubes to your current setup, ensuring a seamless integration with your existing heat exchanger system.

When Is This Service Right for You?

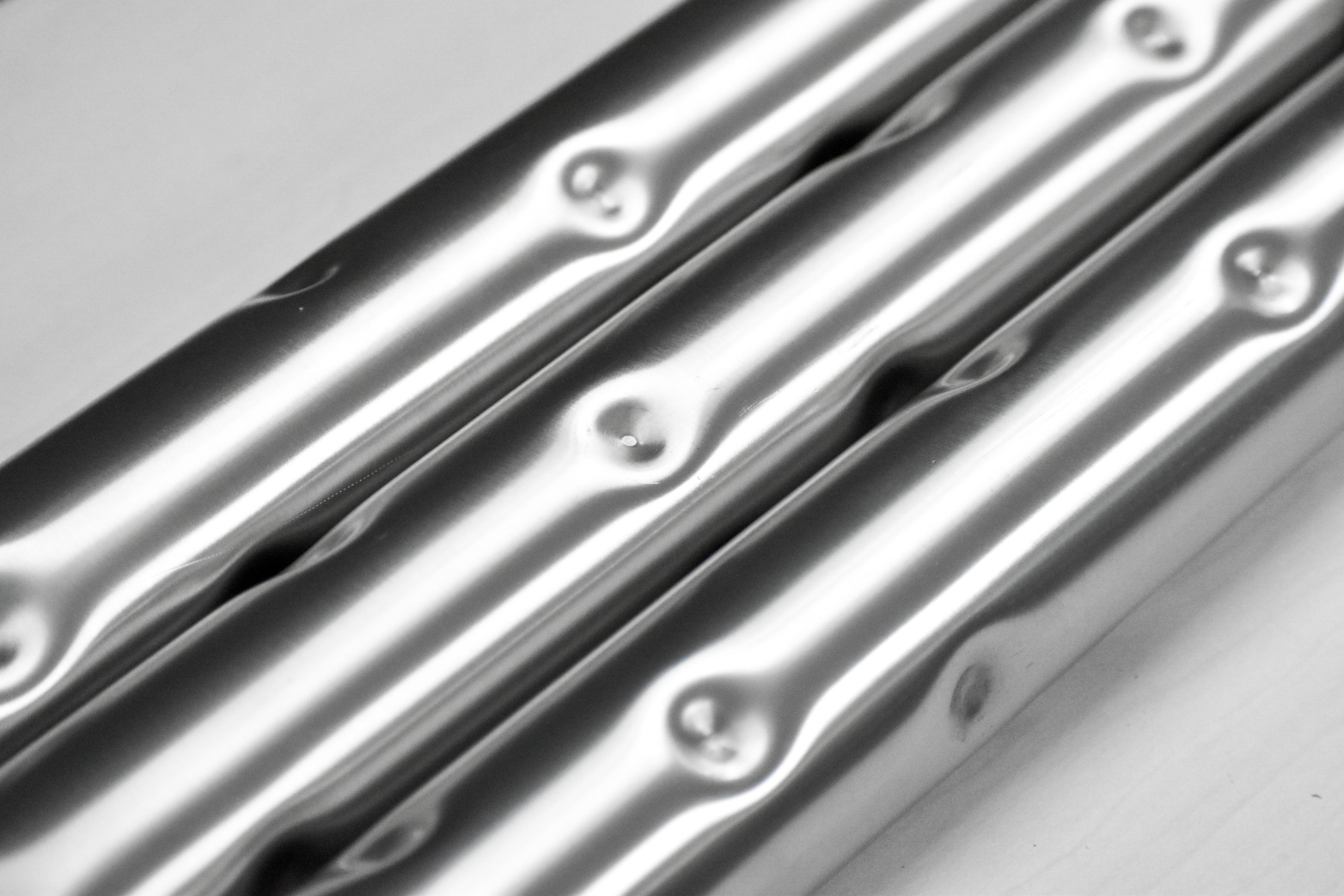

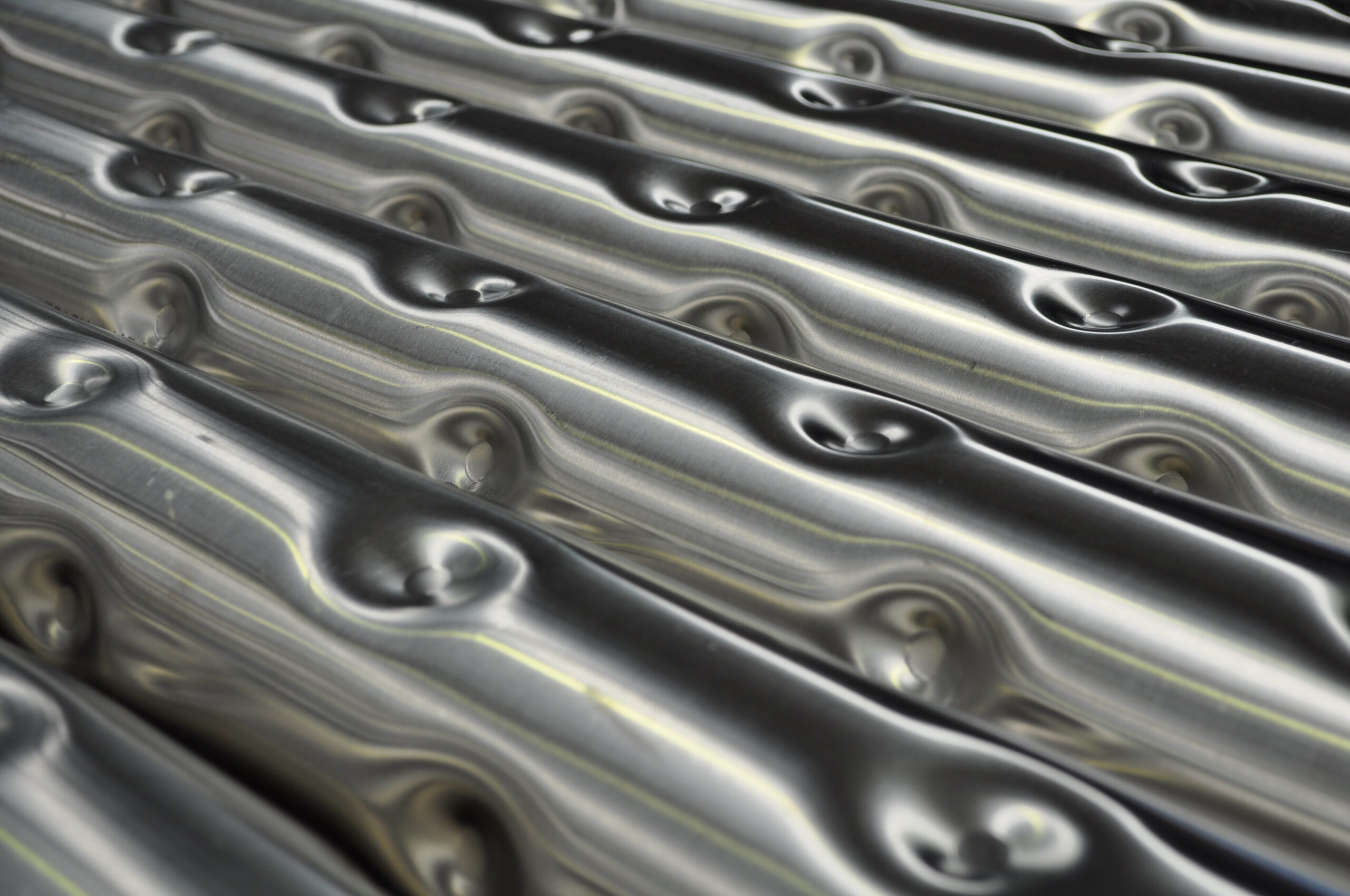

Dimpleflo™ Profile Range

The Dimpleflo™ heat exchanger range is available in various dimple profiles, each designed to suit specific fluid types and processing conditions. This flexibility ensures optimal thermal performance and operational efficiency across a wide range of industrial applications.

Shallow Dimple Profile

Ideal for low-density media such as gases and vapours, offering efficient heat transfer with minimal pressure drop.

Standard Profile Range

The standard profile, best suited for water, oil, and other service fluids, providing a balance of flow and heat transfer performance.

Heavy Profile Range

Designed for high-viscosity or fouling fluids, this profile ensures robust performance and easy cleaning in demanding process environments.

Dimpleflo™ Heat Exchanger Technology

Features & Capabilities

Dimpleflo™ is engineered for high performance and durability in demanding industrial applications. Its unique dimpled tube design enhances fluid dynamics, allowing for greater heat transfer efficiency, compact installation, and flexibility across a wide range of processes.

Enhanced Fluid Turbulence

The dimpled surface promotes turbulent flow and high Reynolds numbers, significantly improving heat transfer rates.

High-Pressure Capability

Designed to withstand internal pressures of up to 25 bar, making it ideal for demanding process conditions.

High-Temperature Performance

Handles high-temperature applications, including steam, withstanding up to 250°C.

Versatile Fluid Handling

Compatible with the heating and cooling of any pumpable fluid—ideal for diverse industrial applications.

Custom Dimple Configurations

Varying Dimple Design Combinations for Specific Duties.

Space-Saving Compact Design

Existing heat exchangers han be re-tubed with Dimpleflo tubing and achieve up to 50% additional capacity in the same shell or footprint.

Enhanced Fluid Turbulence

The dimpled surface promotes turbulent flow and high Reynolds numbers, significantly improving heat transfer rates.

High-Pressure Capability

Designed to withstand internal pressures of up to 25 bar, making it ideal for demanding process conditions.

High-Temperature Performance

Handles high-temperature applications, including steam, withstanding up to 250°C.

Versatile Fluid Handling

Compatible with the heating and cooling of any pumpable fluid—ideal for diverse industrial applications.

Custom Dimple Configurations

Varying Dimple Design Combinations for Specific Duties.

Space-Saving Compact Design

Existing heat exchangers han be re-tubed with Dimpleflo tubing and achieve up to 50% additional capacity in the same shell or footprint.

Dimpleflo™ Heat Exchanger Technology

The Dimpleflo™ Advantage

With decades of experience in heat exchanger design, fabrication, and maintenance, Teralba Industries is the trusted partner for Australian manufacturers across food, beverage, pharmaceutical, chemical, and industrial sectors. Our team delivers expert guidance, high-quality workmanship, and a commitment to helping you get the most from your investment.

Frequently Asked Questions

Find quick answers to common inquiries about our products, services, and technical specifications to help you make informed decisions with ease.

Any more questions? Please contact us.

What is a Dimpleflo™ Retubing Solution?

A Dimpleflo™ retrofit is a specialised service that replaces the internal tubes of your existing heat exchanger with Dimpleflo™ dimpled tubes, without needing to replace the entire unit. This restores thermal efficiency, reduces energy costs, and extends equipment life — all while avoiding major capital expenditure.

How do Dimpleflo™ dimpled tubes improve heat exchanger performance?

Dimpleflo™ tubes feature a unique, patented dimple pattern that disrupts fluid flow to increase turbulence. This dramatically enhances heat transfer efficiency, improves thermal response time, and helps reduce product fouling compared to standard smooth tubes.

Can any heat exchanger be retrofitted with Dimpleflo™ tubes?

Most shell-and-tube and tubular heat exchangers can be retrofitted with Dimpleflo™ tubes, depending on the condition of the shell and existing setup. Our engineering team assesses compatibility and custom-manufactures the dimpled tubes to fit your unit precisely.

Is a retrofit cheaper than replacing the entire heat exchanger?

Absolutely. A Dimpleflo™ retrofit can save up to 70% of the cost of a full heat exchanger replacement. It also minimises downtime, plant disruption, and installation costs — making it a cost-effective, low-risk solution for businesses of all sizes.

How long does the Dimpleflo™ retrofit process take?

In most cases, the retrofit process takes only a few days, depending on the complexity and scale of your system. Unlike full unit replacements that can take weeks, Dimpleflo™ retrofits are designed to minimise production interruption.

What industries use Dimpleflo™ retrofit services?

Dimpleflo™ retrofits are trusted across a wide range of industries, including:

Food and dairy processing

Beverage and brewing

Pharmaceutical and nutraceutical manufacturing

Chemical and industrial processing

These sectors benefit from improved hygiene, faster thermal exchange, and reliable performance.

Will retrofitting affect my system’s hygienic compliance?

No — in fact, Dimpleflo™ tubes are manufactured to meet strict hygienic and sanitary standards, including those required in food, dairy, and pharmaceutical applications. The smooth welds and unique design reduce fouling and make cleaning easier.

Do I need to modify my existing equipment or piping?

Not at all. One of the key advantages of a Dimpleflo™ retrofit is that it preserves your existing setup. The new tubes are custom-engineered to integrate seamlessly into your current heat exchanger, with no need for pipework alterations or structural changes.

What is the typical ROI on a Dimpleflo™ retrofit?

Most clients experience a return on investment within 6 to 12 months, thanks to improved energy efficiency, reduced downtime, and increased process throughput. The savings in utility and maintenance costs alone often justify the retrofit quickly.

Who performs the Dimpleflo™ retrofitting service?

All Dimpleflo™ retrofits are delivered by Teralba Industries, the original designer and manufacturer of Dimpleflo™ technology. With 40+ years of heat exchanger innovation, Teralba’s technicians ensure a smooth, expert-led retrofit process from start to finish.

What is a Dimpleflo™ retrofit?

A Dimpleflo™ retrofit is a specialised service that replaces the internal tubes of your existing heat exchanger with Dimpleflo™ dimpled tubes, without needing to replace the entire unit. This restores thermal efficiency, reduces energy costs, and extends equipment life — all while avoiding major capital expenditure.

How do Dimpleflo™ dimpled tubes improve heat exchanger performance?

Dimpleflo™ tubes feature a unique, patented dimple pattern that disrupts fluid flow to increase turbulence. This dramatically enhances heat transfer efficiency, improves thermal response time, and helps reduce product fouling compared to standard smooth tubes.

Can any heat exchanger be retrofitted with Dimpleflo™ tubes?

Most shell-and-tube and tubular heat exchangers can be retrofitted with Dimpleflo™ tubes, depending on the condition of the shell and existing setup. Our engineering team assesses compatibility and custom-manufactures the dimpled tubes to fit your unit precisely.

Is a retrofit cheaper than replacing the entire heat exchanger?

Absolutely. A Dimpleflo™ retrofit can save up to 70% of the cost of a full heat exchanger replacement. It also minimises downtime, plant disruption, and installation costs — making it a cost-effective, low-risk solution for businesses of all sizes.

How long does the Dimpleflo™ retrofit process take?

In most cases, the retrofit process takes only a few days, depending on the complexity and scale of your system. Unlike full unit replacements that can take weeks, Dimpleflo™ retrofits are designed to minimise production interruption.

What industries use Dimpleflo™ retrofit services?

Dimpleflo™ retrofits are trusted across a wide range of industries, including:

Food and dairy processing

Beverage and brewing

Pharmaceutical and nutraceutical manufacturing

Chemical and industrial processing

These sectors benefit from improved hygiene, faster thermal exchange, and reliable performance.

Will retrofitting affect my system’s hygienic compliance?

No — in fact, Dimpleflo™ tubes are manufactured to meet strict hygienic and sanitary standards, including those required in food, dairy, and pharmaceutical applications. The smooth welds and unique design reduce fouling and make cleaning easier.

Do I need to modify my existing equipment or piping?

Not at all. One of the key advantages of a Dimpleflo™ retrofit is that it preserves your existing setup. The new tubes are custom-engineered to integrate seamlessly into your current heat exchanger, with no need for pipework alterations or structural changes.

What is the typical ROI on a Dimpleflo™ retrofit?

Most clients experience a return on investment within 6 to 12 months, thanks to improved energy efficiency, reduced downtime, and increased process throughput. The savings in utility and maintenance costs alone often justify the retrofit quickly.

Who performs the Dimpleflo™ retrofitting service?

All Dimpleflo™ retrofits are delivered by Teralba Industries, the original designer and manufacturer of Dimpleflo™ technology. With 40+ years of heat exchanger innovation, Teralba’s technicians ensure a smooth, expert-led retrofit process from start to finish.

Want to restore your heat exchanger’s efficiency without the massive cost of replacement?